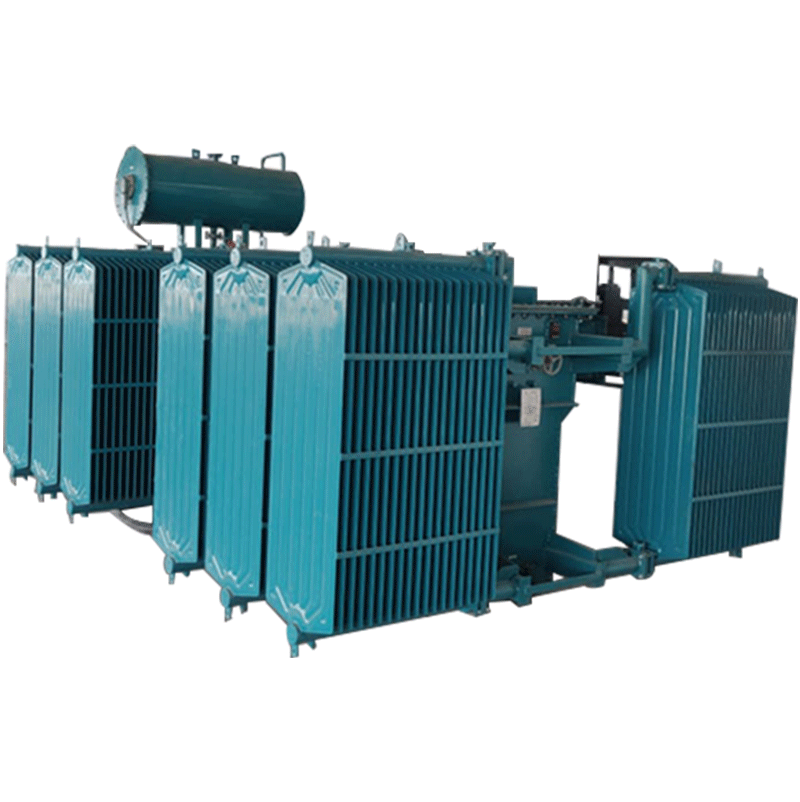

Furnace Transformers are developed for melting of ferrous and non-ferrous metal. In accordance with induction/ heating furnace,

Induction Furnace has coil structured from heavy copper tubing. it is developed and turned to the inverter circuit which applies a medium frequency (generally 500 Hz or 1000 Hz) voltage to the induction coil. The magnetic field offered by the induction coil induces eddy currents for developing heat. Medium frequency is required to enhance the rate of heat generation.

Technical Specification

| Range | Up to 20 MVA |

| Voltage Class | 11 KV, 22 KV, 33 KV On LV side Upto 1.3 KV |

| Protection | Up to 15000Amps |

| Cooling | AF, ONAN |

| Winding Material | Copper with multiple paper covering , A & F class |

| Vector Group | Dyn11, Dyn5, Dyn1, Dd0, YD11, YD1 or other specified by customer |

| Vector Group | Dyn11, Dyn5, Dyn1, Dd0, YD11, YD1 or other specified by customer |

| No. of phase | 3 phases |

| Frequency | 50/60 Hz |

| Tap Range | ±10% in on load and ±7.5% in off load or other specified by customer |

| Applicable Standards | IS-2026, IEC 60076 |

| Painting | Epoxy, Polyurethane or specified by customer |

| Type | Indoor/ Outdoor Pad Mounted |